Types of damp-proof courses

|

These terraced houses near Bridport were made from brick with the lower courses of the wall made of Bothenhampton stone (also known as Baunton stone). This local stone is naturally impervious to water and acts as a damp-proof course. |

Contents |

[edit] Introduction

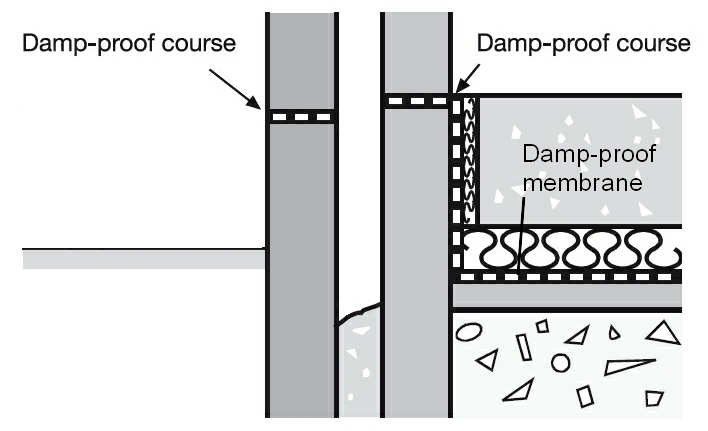

Rising damp is caused by capillary action drawing moisture up through the porous elements of a building’s fabric. Rising damp, and some penetrating damp, can be caused by faults to, or the absence of, a damp-proof course (DPC) or damp-proof membrane (DPM).

A damp-proof course is a horizontal barrier built into the walls. It is typically located 150 mm above ground level.

[edit] Standards

In the construction of new buildings, DPCs are required to prevent rising damp. In some situations they are also required to prevent penetrating damp.

Approved document C of the Building Regulations, Site preparation and resistance to contaminants and moisture, suggests that a DPC may be a, ‘…bituminous material, polyethylene, engineering bricks or slates in cement mortar or any other material that will prevent the passage of moisture.’

|

A DPC made from polyethylene may be referred to as a DPM. For more information, see Damp proof membrane DPM.

Standards for DPCs are provided in BS 8215:1991 Code of practice for design and installation of damp-proof courses in masonry construction.

[edit] Materials used for DPCs

DPCs can be created by impervious materials or techniques, including:

- Bitumen roll.

- Slates and cement mortar.

- Mastic asphalt.

- Lead or copper sheeting.

- Tar and pitch.

- Engineering bricks.

- Chemical injections.

[edit] Bitumen roll DPC

Bitumen is a petroleum-based hydrocarbon that occurs naturally as a concentrated substance in oil sands and pitch lakes. For standard DPC purposes, bitumen roll DPC may consist of a thin layer of non-viscous bituminous material made with a waterproof hessian cloth base. Extra protection may be provided by using a thin layer of copper or lead foil interlining instead of hessian cloth.

|

Hessian cloth like this can strengthen or reinforce the bitumen roll. This material is also sometimes referred to as burlap. |

Bitumen roll is one of the least expensive forms of DPC. It may also be one of the easiest to use.

[edit] Slates and cement mortar DPC

It is possible to create an effective form of DPC by constructing a double layer of slates in cement mortar. Any type of slates can be used, and the mortar can be made up of two parts clean sand and one part Portland cement.

|

Ancient Romans used slate without mortar as a DPC to block rising damp. In this example from the Hardknott Roman fort in Cumbria, the slate also serves to separate the original Roman construction (below) from modern reconstruction (above). |

This measure requires little specialised skill and can be a viable alternative if bitumen roll is not available or an abundance of slate exists.

[edit] Mastic asphalt DPC

To use this method of DPC requires temperatures high enough to melt natural asphalt. Pure bitumen is then added to the heated asphalt until a workable consistency is achieved. This substance is then spread on the wall.

|

Natural asphalt used as DPC material may require two separate applications to prevent cracking. |

This can be an expensive method and may require an advanced level of expertise.

[edit] Lead or copper sheeting DPC

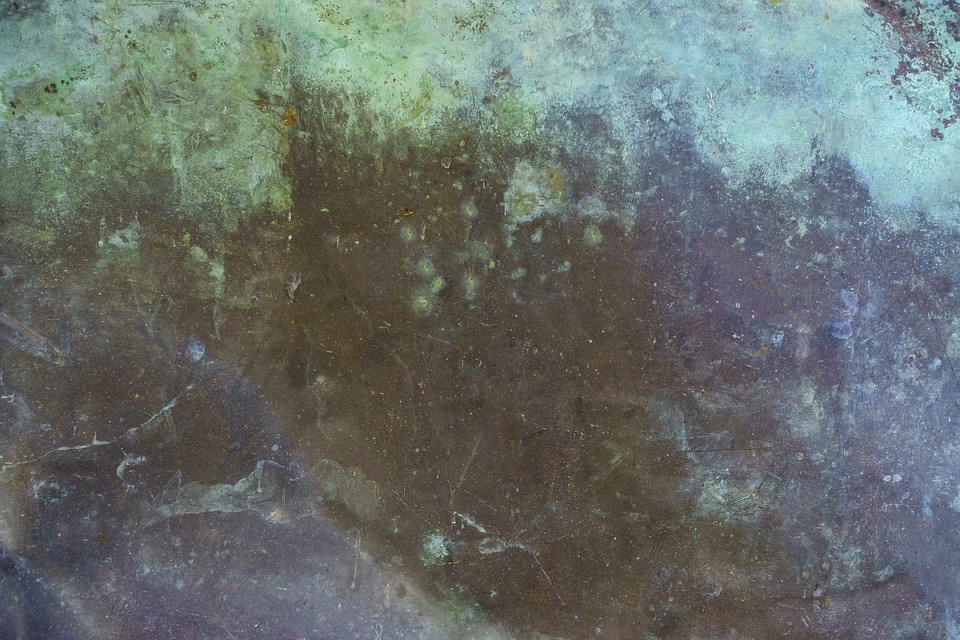

Sheets of lead or copper provide the same type of DPC as bitumen rolls. The technique for application is also quite similar.

|

When used for DPC, copper sheets may become corroded over time. |

In some instances, non-ferrous metallic materials may be susceptible to decay when attacked by salts that might occur in damp mortar. This can reduce the effectiveness as the thickness of the material decreases.

[edit] Tar and pitch DPC

When sand is added to tar and pitch and then melted in a boiler, the resulting substance can form an effective and inexpensive DPC. The molten material is poured onto the wall to cover the surface.

Mortar should be placed on the edges of the wall to prevent the molten material from running down the sides of the wall. Once the mixture cools, it will solidify and form a waterproof layer.

In some instances, this substance can become brittle and may crack in extremely cold temperatures.

[edit] Engineering bricks

Sometimes referred to as impervious brick, these bricks are stronger and less porous than other types of brick.

|

Near Chester Bridge, a high water benchmark was cut into the softer red brick rather than the adjacent, much harder, blue engineering bricks. |

Early forms of impervious bricks were sometimes referred to as blue bricks. A higher firing temperature typically gave these bricks their blue colour (although in some instances they may appear black).

Engineering bricks can be used to create an inexpensive and effective DPC when bedded in Portland cement mortar. A course of one or two of these impervious bricks is typically sufficient.

Modern low absorption or DPC engineering bricks fall into two categories: DPC1 (with a maximum water absorption rate of 4.5%) and DPC2 (with a 7% maximum water absorption rate).

[edit] Chemical injection DPC

Some older buildings may require a chemical injected DPC. This can create a continuous chemical barrier to rising damp. For more information, see Chemical injected DPC.

[edit] Related articles on Designing Buildings

Featured articles and news

Scottish parents prioritise construction and apprenticeships

CIOB data released for Scottish Apprenticeship Week shows construction as top potential career path.

From a Green to a White Paper and the proposal of a General Safety Requirement for construction products.

Creativity, conservation and craft at Barley Studio. Book review.

The challenge as PFI agreements come to an end

How construction deals with inherited assets built under long-term contracts.

Skills plan for engineering and building services

Comprehensive industry report highlights persistent skills challenges across the sector.

Choosing the right design team for a D&B Contract

An architect explains the nature and needs of working within this common procurement route.

Statement from the Interim Chief Construction Advisor

Thouria Istephan; Architect and inquiry panel member outlines ongoing work, priorities and next steps.

The 2025 draft NPPF in brief with indicative responses

Local verses National and suitable verses sustainable: Consultation open for just over one week.

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.